Dental implant stereoscopy

Introduction

Dental implants have revolutionized restorative dentistry, providing long-lasting and effective solutions for tooth loss. Central to their success is the use of titanium, a material chosen for its exceptional compatibility with human biology. In this blog, we delve into the critical role of Scanning Electron Microscopy (SEM) in enhancing the effectiveness of dental implants.

SEM and Dental implant stereoscopy

A dental implant acts as a substitute for the root part of a missing tooth and is typically made from titanium. This metal is known for its robust biocompatibility—essentially, the human body accepts titanium without adverse reactions, which is crucial for any material that is to be integrated into bone.

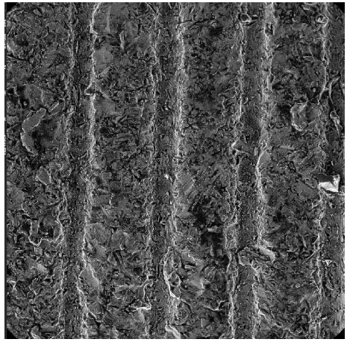

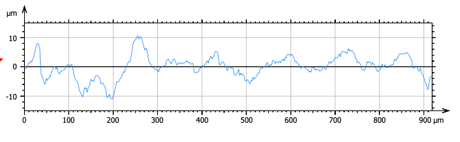

To improve the integration of an implant, the surface of the titanium screw is deliberately roughened. This texture increases the surface area in contact with the bone, enhancing the bone’s ability to grow against and around the implant. This process, known as osseointegration, is critical for the stability and longevity of the implant.

Scanning Electron Microscopy (SEM) plays a pivotal role in the development and refinement of dental implants. By producing high-resolution images, SEM allows researchers and manufacturers to meticulously analyze the surface roughness of titanium implants. The technology provides detailed visuals that are crucial for assessing the efficacy of surface treatments intended to optimize osseointegration.

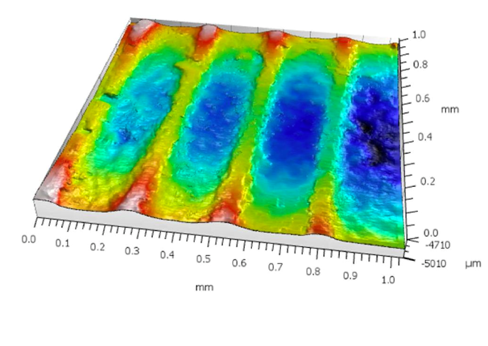

A particularly valuable technique in this context is stereoscopy using SEM. By taking two SEM images at different angles (eucentric tilt), a stereo image can be created. This allows for a three-dimensional visualization of the implant’s surface, providing a more comprehensive analysis of its topography and roughness. Such precise measurement is instrumental in ensuring the maximum effectiveness of bone integration.

Advanced SEM models, like the Semplor NANOS, can be seamlessly integrated with sophisticated analytical software, such as Mountains software. This integration allows for automatic and precise analysis of the SEM images. Users can measure, visualize, and quantify the surface roughness with unprecedented accuracy and ease, making it an indispensable tool in the quality control of dental implants.

- Eucentric tilt (standard feature NANOS)

- Tilt angle -/-15 up to + 40 degrees

- SE or BS images

- Mountains software