Dentist drill bit imaging using eucentric tilt

Scanning electron microscopes play a crucial role in observing the microscopic structure of materials used in dental applications. They are also essential for identifying foreign components and testing compatibility.

Dental drill bits, commonly referred to as dental burs, are essential tools in modern dentistry, enabling precise and efficient cutting, grinding, and shaping of hard tissues such as teeth and bone. These tiny, high-precision instruments are typically made from materials like tungsten carbide or diamond, ensuring the durability and sharpness required for the demanding conditions of dental procedures. The effectiveness of a dental drill bit lies not only in its material composition but also in the intricate design of its cutting edges, which must maintain sharpness while withstanding high rotational speeds and considerable pressure during use.

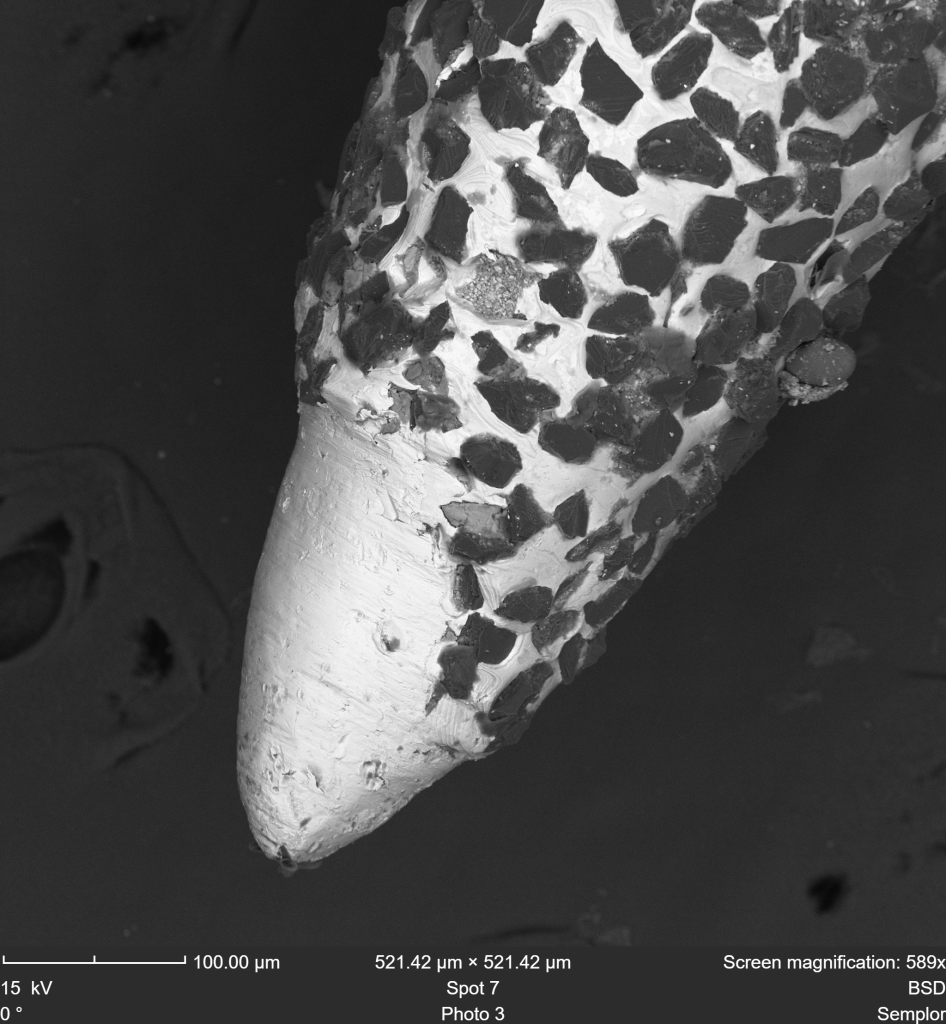

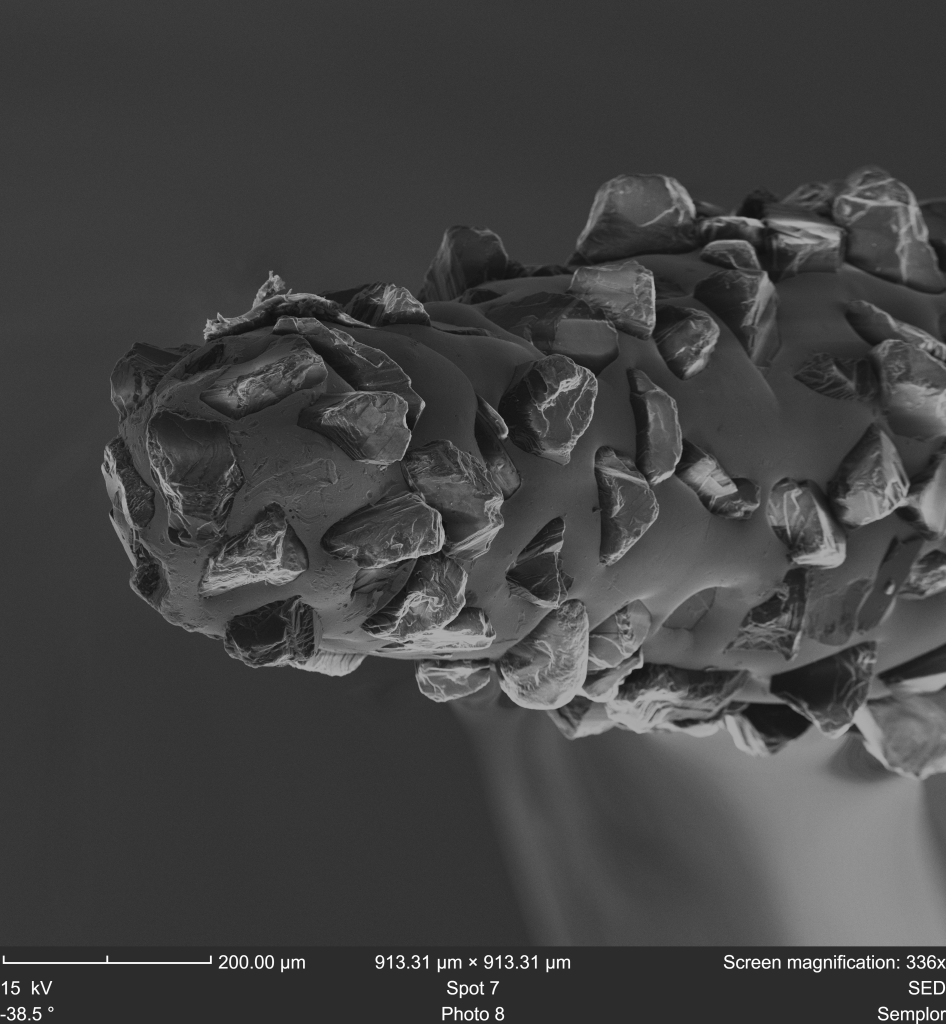

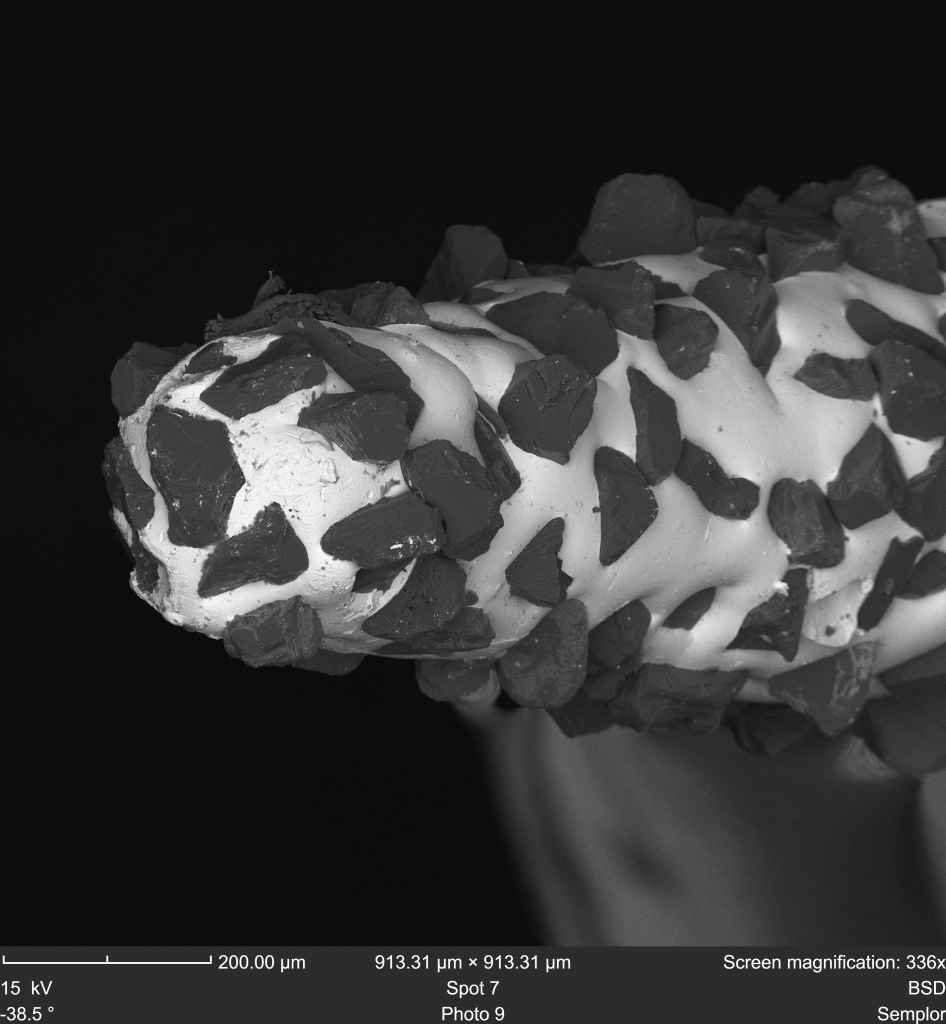

One of NANOS’ standout features is the eucentric tilt, allowing you to manually tilt your sample up to 55 degrees while maintaining perfect focus—a truly unique capability. This feature is perfect for imaging drill bits. The images in Figures 1 and 2 are taken using a tilt angle of -38,5 degrees. The NANOS stage arm has a dedicated drill bit holder for imaging the tips of drill bits or e.g. needles.

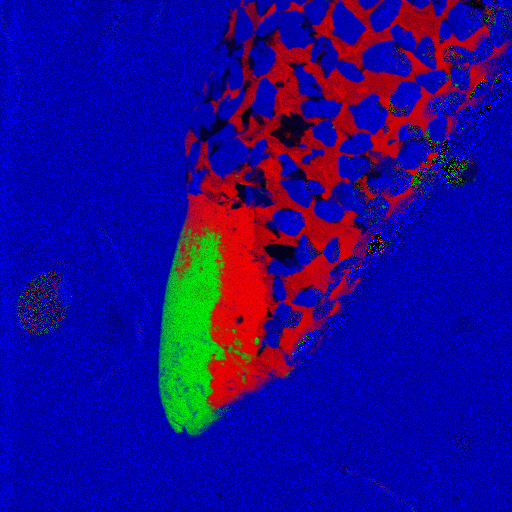

The seamless integration of SEM imaging and EDS mapping in modern tabletop SEMs allows for faster sample analysis. The dentist drill bit is conductive, so it can be looked at in high-vacuum mode, at 20kV for optimal resolution in EDS. In Figure 4 we can find the result of EDS analysis on a used dentist drill bit, indicating iron (Fe) in green, Nickel (Ni) in red and Carbon (C) in blue.

The microanalysis of dental drill bits using SEM is crucial for understanding their material composition and wear patterns. Advanced NANOS SEM features, like eucentric tilt, BSD, and SED, allow for precise imaging and elemental mapping. This ensures a detailed evaluation of the drill bits, helping to improve their design and durability in dental applications.